June 27, 2019

by Dafyd Martindale

On Wednesday I had the opportunity to inspect Coopers Gap, Australia’s largest wind farm when it’s completed in May or June next year.

The invitation was extended by constructors AGL, and it was one I was keen to accept – not only on my own behalf, but on behalf of all southburnett.com.au’s readers who share my interest in this remarkable piece of engineering.

Over the past 11 years, I’ve followed every twist and turn of this renewable energy project, from the early days when then-project developers Windlab Systems and Investec Bank first floated the idea with the local community through to when the first turbines, now owned by PARF, delivered power to the grid this week.

Just after dawn on Wednesday, I guided my car from Kingaroy along the Bunya Highway through an early morning shower towards Coopers Gap.

A little past Kumbia I began to see the wind farm’s turbines on the horizon – small, elegant but increasingly familiar outlines that steadily became bigger as I drew close.

Around 7:30am, I turned into Niagara Road to begin looking for the wind farm’s site office.

Here’s what I saw.

* * *

I’d been told the site office was located about 7km along Niagara Road, past the Powerlink substation completed in April.

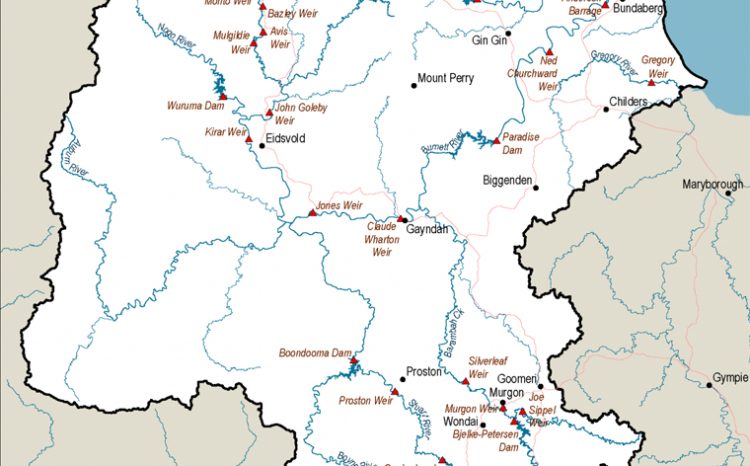

The last time I’d been along Niagara Road was about a year ago, when I saw AGL’s initial site preparations for the substation, which transfers energy from the wind farm’s 123 turbines and feeds it into the grid.

At that time Niagara Road was an unremarkable strip of broken bitumen and dirt that twisted its way past cattle grazing paddocks.

But this time, not far past the substation’s front gates, I found myself driving through a landscape where wind farm turbines towered over me at every point.

They were so tall I couldn’t look up at them without running the risk of driving off the road.

Which meant that by the time I found the site office’s entry near the Bilboa Road junction, I felt I’d left the everyday world and entered a valley of giants.

* * *

AGL’s site office turned out to be a crowded collection of about a dozen demountable huts surrounded by a car park full of 4WDs.

Inside the huts, workers were quietly toiling with computers, charts and reports on the myriad details that come with any major engineering project.

Outside, the walls sported colour-coded maps showing the location of every turbine in Coopers Gap and each one’s current state of construction, along with extensive collections of workplace health and safety reports.

Not long after I arrived I was greeted by site manager Michael Yeo, who introduced me to two local farmers who would be joining us on the trip: Michelle Davis and Judy Schafferius.

Michael gave us all hard hats, high-vis vests, gloves and goggles to wear: “AGL takes the safety of everyone very seriously,” he said.

Then he bundled us into a large 4WD and we headed deep into the wind farm up roads that – at times – seemed to be at almost a 45-degree angle.

* * *

The weather at Coopers Gap on Wednesday was blustery and cold, with scuds of rain patterning the windscreen as we moved towards our goal: a high hill that Michael assured us would provide a great view over the project.

We slowly made our way along one of the 91km of dirt access roads AGL has built for the wind farm. It took us up, up, up a hill that eventually topped out on a small rocky plateau.

From there, we could look out across many miles of the Coopers Gap landscape, and see a dozen wind turbine towers jutting out from a low bank of rain clouds sweeping through one of the valleys below.

Nearby, a few turbines at the same altitude loomed over us like giant exclamation marks.

* * *

After we’d taken in the freezing view and exchanged wry comments about why Coopers Gap had been chosen for a wind farm, Michael took us back down the hill.

Our next stop was a more sheltered site where a turbine will soon be erected.

Michael let us look over the tower, blade and blade assembly components that help make up a complete unit.

From a distance, all turbine components look small. But up close, we quickly realised we were the small objects in that landscape – the turbines are huge.

The five separate tubes that make up each turbine’s tower, for instance, are wide enough to accommodate a ladder and an elevator.

Michael said the elevator can lift loads up to 180kg and can be used to transport a worker from the base of a turbine to the nacelle at the top in several minutes (or two workers if they’re prepared to stand very close to each other).

But just in case an elevator fails, each tower also has a ladder that can be used in an emergency.

* * *

The wind turbine blades are also a marvel of modern engineering.

We discovered each blade sports a row of “teeth” at its extreme end, something none of us expected.

Michael said the teeth were there to “cut up” sound waves as the blades span, and were positioned along the end of each blade because sound travelled down to the tip as the turbine rotated.

While I’d known before I came that each blade was about 65m (roughly 215ft) long, it’s one thing to know this and another to stand next to something that appears to stretch away into infinity.

The business end of a turbine blade – the tip – is small enough to fit between your thumb and forefinger and you can make it bounce with a light tap of your hand.

But the opposite end which plugs into the turbine is roughly 2.5m high, ribbed with steel bolts and solid as a rock.

We also marvelled that the whole blade – from the thin end to the bulky one – is one giant, seamless, immaculately formed fibreglass construction without a single join, seam or weld.

“They must have a big factory to make these,” Judy said. We agreed.

Later – looking out over more turbines – we also had the size of these huge constructions confirmed when a tiny black hole opened in the side of one turbine and two tiny figures emerged.

We realised we were looking at the door fitted to the base of each tower; that the two tiny figures were workers; and that – on a human scale – we were all not much more than ants.

Michael told us that initially there had been some difficulties transporting components from the Port of Brisbane to the site, but these had all been smoothed over.

Most of the wind farm’s parts have now been landed and turbine assembly – as we could all see – was proceeding at a rapid pace.

* * *

We also inspected the Powerlink substation and a second substation AGL has built next to it.

Michael told us that in addition to the roads AGL cut through the paddocks, the company had also built 20km of power lines.

There is also 71km of underground cabling laid to connect most of the turbines.

Michael said the reason for the power lines was that while many turbines close to the substation feed their power efficiently through underground cables, distant turbines up to 20km from the substation lose too much sending electricity this way.

Power lines were the most efficient solution to this problem, and that’s what AGL chose to do.

It meant they had to build a collection point next to the substation the lines feed into before making the last few feet to Powerlink’s network.

But – so far – everything is working to plan.

* * *

By the time our tour wrapped up back at the site office, I had to admit I was impressed by AGL’s approach to the project.

I was also deeply impressed by painstaking work construction staff have done, manoeuvering the wind farm’s enormous components into place with tolerances so exacting they’re measured in millimetres.

I have no doubt that in years to come many will return with their children to proudly show them what they helped build, and so they should.

Judy and Michelle told me they had similar feelings.

Both had lived through the project’s early, turbulent years when the very idea of an enormous wind farm straddling the borders of the South Burnett and Western Downs regions had split the local community apart.

But as Coopers Gap has progressed over the past few years, those unhappy days were now quickly slipping into memory.

Both told me they now realise some of the concerns raised about reduced property values or wind farm noise did not really hold water, and probably never did.

Both freely admitted they would benefit from the project (they have turbines on their own properties), but they also feel the wind farm has brought real benefits to the area.

Non-turbine hosting farms within 2km of the wind farm’s boundaries now have free solar power, courtesy of AGL, to compensate for any loss of visual amenity.

And the nearby communities of Cooranga North, Kumbia, Jandowae and Bell have a new source of funding for local projects and events, courtesy of the wind farm’s twice-yearly Community Benefit Fund.

* * *

Judy and Michelle said their one remaining concern is about a viewing platform the South Burnett and Western Downs councils plan to build, probably near the Bilboa Road intersection, so tourists can take photos of the wind farm once it’s operational.

They worry that Niagara Road is too narrow for caravans (it is) and unless this is clearly signposted, accidents could happen.

As I left the wind farm later that morning and slowly made my way back along Niagara Road through more scattered showers, I had to agree they were right.

It is narrow, winding and has lots of blind corners, and both Councils will need to take special care to minimise risks to tourists.

But will tourists come?

I have no doubt they will … for years and years into the future.

Memories of the drive I took through that valley of giant turbine towers will stay with me for a long time.

Related articles:

- Coopers Gap Goes Online

- Wind Farm Ready To Power Up

- Substation Ready To Fire Up

- Wind Farm Opening Pushed Back

- Blade Delays Slow Wind Farm

- First Turbines Erected At Wind Farm

- Wind Farm Signs $6.7m Road Deal

- First Components Arrive At Wind Farm

- Joint Push To Fix Phone Services

- Wind Farm Work Well Underway

- AGL Asks MPs For Help To Solve Mobile Problems

- Job Openings At Wind Farm

- KCCI Urges Businesses To Submit EOIs

- Substation Build Gets Underway

- Council Tells Wind Farmers To Pay Up

- Construction Starts On Wind Farm

- Full Steam Ahead For Wind Farm

A good read and you covered it well. If councils do work on the road maybe it will bring some tourist dollars into the area; will have a drive out there when COVID-19 has moved on.