July 9, 2013

Bean Growers Australia is just weeks away from completing a $3 million upgrade of their Kingaroy plant, which has seen the installation of 20 new silos, new grading and sorting equipment, and as a finishing touch … six polishers.

Polishers? Many of BGA’s beans end up in the high-grade export market where customers prefer their beans dust-free and shiny.

BGA can now send their beans down parallel polishing lines, ensuring a nice “double” polish.

The massive upgrade – which has increased the handling capacity of the plant – is linked to the fact that navy beans are no longer the mainstay of the BGA business.

BGA will be marking its golden anniversary next year and for most of that time navy beans (ie baked beans) have been their staple. But the market changed when Heinz withdrew from Australia about 12 years ago.

In the past, BGA was processing 7000-8000 tonnes of navy beans; this has now dropped to 3000 tonnes but the plant is handling 20,000 tonnes of product.

“We have become a more diversified business,” BGA Managing Director Lloyd Neilsen said.

“Navy beans are only a percentage of our business now.”

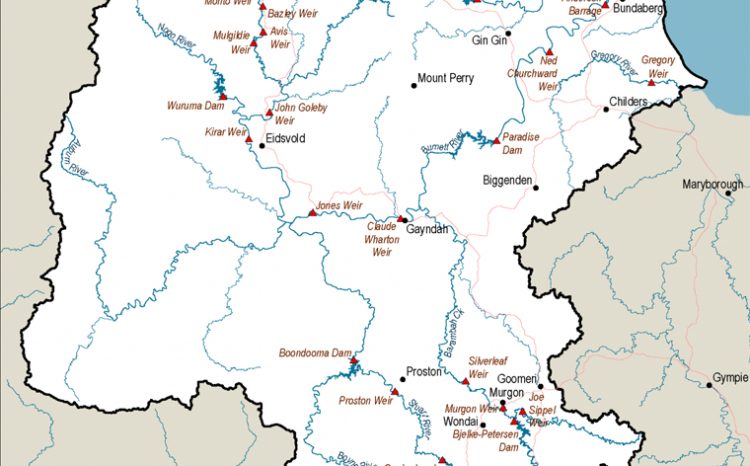

Mung beans form about 40 per cent of the current business, alongside adzuki beans, popping corn and soy beans. Growers are located from the Riverina to the Atherton Tableland, and everywhere in between.

India is BGA’s biggest export customer. Also buying mung beans are Indonesia, the Philippines, Malaysia, Sri Lanka and Vietnam; adzuki beans are being sent to Japan and Taiwan.

Mr Neilsen said as a result of the change in focus, a 3500 tonne bulk shed which had been used to store navy beans was no longer being utilised to capacity.

So this was demolished and replaced with 20 silos ranging in capacity from 165 tonnes to 205 tonnes. The separate silos mean “segregated” crops and better control over quality.

The new storage also has improved aeration and automatic controllers to ensure a stable temperature.

Another aim of the upgrade was to get the plant working more efficiently as BGA is competing against export markets where labour costs are much lower. The result is greater plant capacity with the same number of employees.

New elevators and conveyors have been installed to eliminate double handling.

Two more conveyors will be installed over the next fortnight and the upgrades will be complete … now all BGA needs is a good season.

“It is frustrating because we could handle a significantly larger crop because of the storage and processing ability but we will have to wait another 12 months to test ourselves,” Mr Neilsen said.

The 2013 floods – coming on top of the 2011 floods – knocked around key local growers, especially in the Byee and Brooklands areas.

‘We consider them part of our family. They are very skilled at growing beans and run very efficient businesses. The floods have put them under a tremendous amount of pressure through no fault of their own,” he said.

“Some of these farmers couldn’t plant a winter crop. It is going to be 12 months or more before their land is going to be earning anything.

“The general public don’t tend to see that.”