April 18, 2013

A three-year trial of remotely controlled, driverless coal trucks will begin at Stanwell’s Meandu Mine on April 29.

Hitachi Construction Machinery (Australia) announced last week that trials of its Autonomous Haulage System (AHS) would begin when the first of three trucks arrive from Japan.

The trials are part of plans by Hitachi to develop a comprehensive suite of technologies aimed at delivering automated solutions to the mining industry by 2017.

A variety of advanced drive and traffic-control components will be installed on board the trucks.

When these are combined with wireless communications and a fleet management system, the loading, haulage and dumping operation will be completely automated.

The trucks will use a highly advanced GPS system to control their location, speed and direction.

The GPS system has the ability to identify haul roads, intersections and mine locations such as loading areas, stockpiles and crushers.

The trucks also have a control system that allows precise speed control, helping them to safely negotiate steep slopes at the mine.

HCA’s General Manager of Mining Mr Eric Green said the trial would develop automated mining trucks that can interact with other people-operated mining equipment.

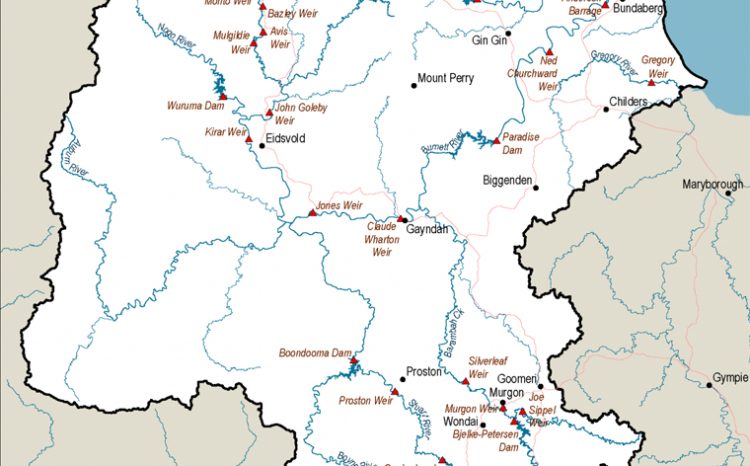

Hitachi says the South Burnett will get an estimated $1.8 million financial boost from the trial in the next two years, with around 15 Hitachi engineers and other experts living in the region and local contractors to be used for specific jobs.

“People can expect to see Hitachi personnel in the South Burnett in coming weeks,” Mr Green said.

“Hitachi chose the South Burnett for this trial because of easy access for staff and international visitors arriving in Brisbane,” he said.

“We have worked closely with Stanwell and Downer, which operates Meandu Mine on behalf of Stanwell, to set up this trial.”

Mr Green stressed that Hitachi had a long way to go to develop the technology, which was in a very early stage.

“We want to do it right and this will take very careful testing over a considerable time,” he said.

Stanwell General Manager Mining Operations Bob Rutten said the company was very pleased that Meandu Mine had been chosen for the high-profile worldwide trial of new mine truck technology.

Mr Rutten said although Hitachi would work within the mine, it would be independent of Stanwell and Downer and it would be at no cost to Stanwell.

He said the trial would not mean a reduction in Stanwell staff numbers at Meandu Mine.

“Indeed, Hitachi informs us they are likely to employ local people, meaning there would be a small increase in jobs at Meandu,” he said.

“Meandu Mine employees who are interested in the trial may also be able to take part.”

Hitachi will also help to maintain Stanwell’s current fleet of Hitachi excavators and trucks at Meandu.

“This sharing of knowledge and expertise will be invaluable in improving our mine operations and we are very pleased with this partnership,” Mr Rutten said.

Hitachi staff will arrive in the South Burnett in coming weeks to assemble the first of three automated mine trucks.

They will then be replaced by a team of Hitachi engineers who will oversee the trial for at least three years.

A number of international visitors, including Hitachi personnel from Japan, are likely to come to the South Burnett to inspect the trial program.

* * *

Automated mining trucks are not a new concept in Australia.

Rio Tinto is also rolling out a fleet of 150 automated Komatsu trucks at its Pilbara iron ore operations in Western Australia as part of a two-year trial.

Since this trial began, the autonomous trucks have operated every day, 24 hours a day.

They have moved more than 42 million tonnes of material in approximately 145,000 cycles and travelled more than 450,000km.

Rio Tinto controls the trucks from its Operations Centre in Perth, 1500km away.