July 29, 2014

The large metallic cube which appeared in Gore Street, Murgon, a few months ago is a massive vote of confidence in the future employment prospects for the workers at The Gumnut Place.

The cube is a gas-fired heat-treatment kiln especially built to treat the thousands of wooden pallets manufactured every month by the workers at Gumnut.

It treated its very first load last week.

The kiln was built by South Burnett CTC at a cost of more than $200,000, including a $50,000 grant from the Tarong Community Partnership Fund.

Gumnut workshop supervisor Kevin Gill said untreated wooden pallets, which had been manufactured by Gumnut workers, were slowly heated to a temperature of 56 degrees C inside the kiln.

This temperature is maintained for 30 minutes to ensure any living organisms – bacteria or insects – in the wood are killed. The timber is then allowed to cool gently, ensuring that none of it warps.

This process enables the pallets to be certified for export.

The Gumnut team helped to assemble the massive kiln on site, although they had to also bring in outside expertise, especially cranes.

The kiln body was imported from Europe in pre-fabricated sections; the fans and burners came from Germany.

It took five weeks to build and 50 cubic metres of concrete went into the slab.

The new kiln should help Gumnut expand its pallet business.

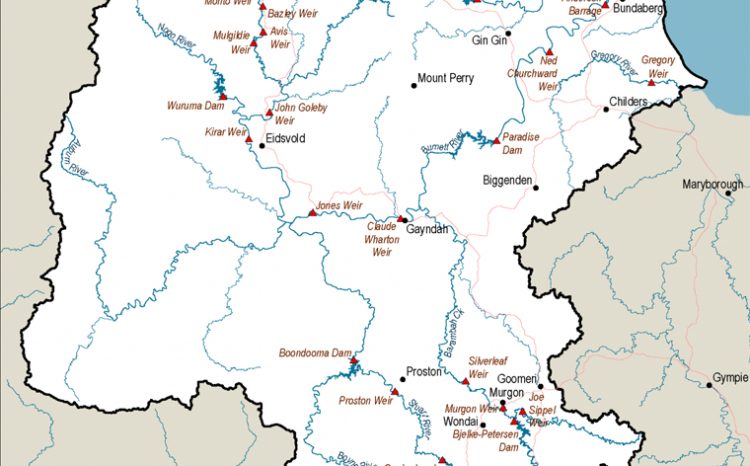

Kevin said Gumnut currently has contracts to supply pallets to businesses which send product to Taiwan, Korea, Indonesia and New Zealand. All these pallets must be certified for export.

At the moment the Gumnut workers are making 2000 pallets a month, but there is a potential for this to be expanded to 4500-5000 a month.

In the past, the workers would treat the pallets for export using methyl bromide gas. It would take 24 hours to treat just one load.

“It is now just five hours, which gives the opportunity for a lot more volume,” Kevin said.

Gumnut provides employment for workers with a disability.

Each gang of workers makes between 160 and 180 pallets a day in the workshop beside the kiln.

They process 24 tonnes of timber a week, which is delivered on semi-trailers direct from Wamuran Timbers.

The new kiln is now certified for export.

“It is a huge investment in the future and the job security of our employees,” Kevin said.

“And it gives us so much more scope for the future.”

Footnote: Kevin said the Gumnut workers go through an estimated 6.7 million nails every year. But don’t worry … they have nail guns!

Congratulations Kevin Gill and staff for driving this project to a successful conclusion. Congratulations to the CTC Senior Staff and Board for backing this project to support Gumnut Place and the local community.

Also thank you to Tarong Community Partnership Fund for their generous contribution. Creating history in our community.